Introduction of Zirconia Ceramics

Zirconia ceramic is white, yellow or gray when it contains impurities, generally contains HfO2, and is not easy to separate. There are three crystalline states of pure ZrO2 under normal pressure.

The production of zirconia ceramics requires the preparation of powders with high purity, good dispersion properties, ultra-fine particles and narrow particle size distribution.

There are many preparation methods for zirconia ultra-fine powder. The purification of zirconia mainly includes chlorination and thermal decomposition, alkali metal oxidative decomposition method, lime melting method, plasma arc method, precipitation method, colloid method, hydrolysis method, spray pyrolysis method, etc.

There are three crystal forms of zirconia: low temperature monoclinic (m) ZrO2, medium temperature tetragonal (T) ZrO2, and high temperature cubic (C) ZrO2.

Zirconia ceramic performance characteristics:

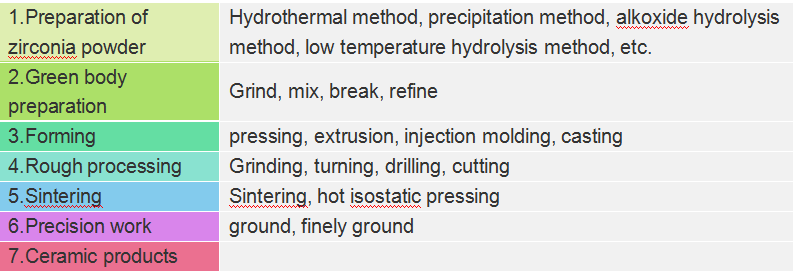

Zirconia ceramic preparation process:

Zirconia ceramic cutting method

Now a new process for cutting zirconia ceramic (diamond wire loop saw cutting) is the most popular and practical. Below the zirconia ceramic cutting video for reference:

Zirconia ceramic industry chain structure diagram

The upstream of the zirconia ceramic industry chain is the raw material of zirconium mineral resources, and the downstream includes four key application areas: refractory materials, functional ceramics, structural ceramics and consumer electronics

Upstream Zirconium Mineral Resources

The main sources of zirconium are monoclinic zircon ore and zircon ore, of which zircon ore is the most widely distributed. The world’s zircon ore reserves are about 40 million tons, and the resource distribution is highly concentrated. About 80% of the global total is distributed in Australia and South Africa.

Application of zirconia ceramics

Zirconia ceramics are widely used in modern industry and life. Let us briefly introduce its main application areas.

1. Mobile phones and other 3C electronic fields

Zirconia ceramics have no signal shielding, drop resistance, wear resistance and folding resistance. At the same time, the appearance is warm and moist like jade, and the hand feel is good. It is widely used in the field of 3C electronics such as mobile phones. Mainly used for mobile phone backplane and other mobile phone structural parts.

2. The field of smart wear

Compared with metal, zirconia ceramics have better wear resistance, smooth surface, good texture and no oxidation. The famous Swiss “Radar” brand, Apple, Chanel and other well-known brands have launched high-end ceramic watches.

3. The field of optical communication

At present, ceramic ferrules and sleeves are widely used in optical fiber connectors. Ceramic ferrules made of high-strength and high-toughness ceramics can not only meet the requirements of high precision, but also have a long service life and very low insertion loss and return loss.

4. Biomedical field

Due to its high strength, high toughness, corrosion resistance, wear resistance and good biocompatibility, zirconia ceramic materials are most commonly used in the biomedical field as dental restoration materials and surgical tools.

5. Automotive field

The thermal conductivity of zirconia ceramics is small, and the thermal expansion coefficient is relatively large, so the parts used to make the engine combustion chamber have good heat insulation, and at the same time, the thermal expansion is closer to metal materials. Can be used as cylinder head bottom plate, cylinder lining, piston crown, valve seat ring, etc. However, due to the harsh working conditions of the engine, the strength of ceramic parts changes greatly at high temperatures, so there is still a distance from commercial application.

6. Jewelry field

High-precision ceramics are mixed with precious metal alloy powder and fired, and are finally integrated into jewelry design after several precise and strict procedures and repeated machine grinding and polishing. This ceramic is not only lightweight and wear-resistant, but also has anti-allergic properties and is comfortable to wear. It is one of the most fashionable jewelry materials at the moment, and is favored by major jewelry brands.

7. Areas of daily life

Ceramics are the inheritance of thousands of years of Chinese culture. In addition to the above applications, ceramics are ubiquitous in our daily life. Ceramics have the characteristics of high temperature resistance, corrosion resistance, oxidation resistance, high strength, wear resistance, and natural antibacterial properties, which can be used as porcelain bowls, spoons, vases, ceramic knives, etc.

8. Other fields

Zirconia ceramics have good mechanical properties, wear resistance and corrosion resistance. They can be used as ceramic bearings and can also be made into ceramic tools. At the same time, zirconia ceramics are weakly acidic oxides, which can resist the erosion of low or neutral slag (but will be eroded by alkaline slag), and can be made into refractory crucibles for metallurgy. The characteristics of high strength, high toughness and corrosion resistance also make zirconia ceramics have certain applications in petroleum, chemical, mechanical, aviation and other fields.