Reasons for the popularity of SiC compared to traditional silicon wafers

Silicon carbide (SiC) is an unfamiliar term to most people, but it has exploded in popularity in recent years and has become a key third type of semiconductor material in 5G and electric vehicles in the future. With the “Tesla effect” driven by the SiC car boom is just the beginning, with the further increase in the global market penetration of new energy vehicles, the future of the SiC chip industry is unstoppable.

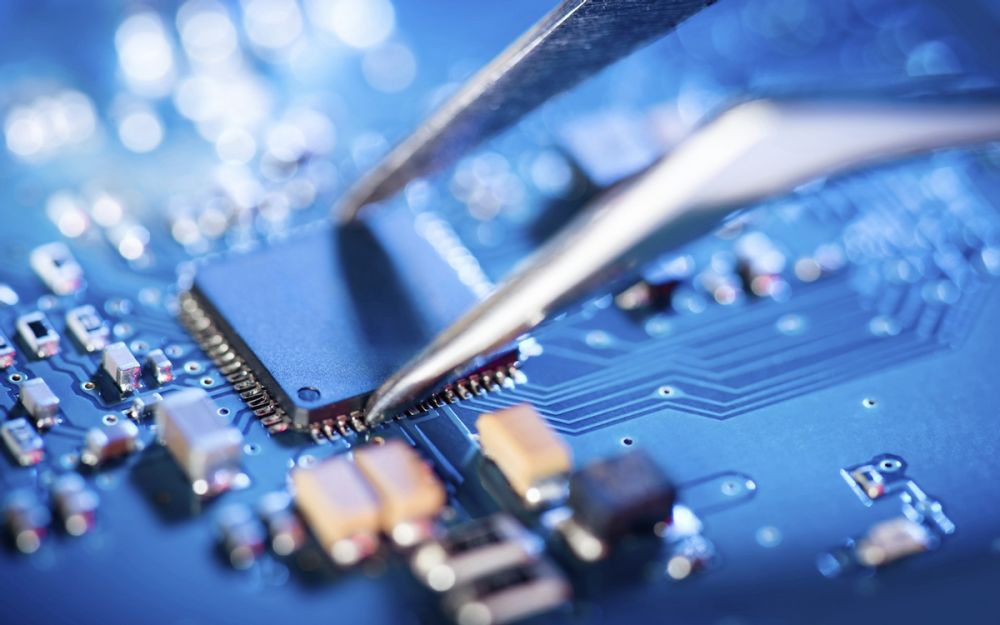

Stepping into new energy vehicles, in order to meet the needs of high current and high voltage, the power semiconductors on board have also been greatly improved. Specifically, the application scenarios of silicon carbide power devices in new energy vehicles include:

Main drive inverter, OBC (on-board charger), fast charging pile, and high-power DC/DC, etc. Among them, the application of SiC in the 800V main motor controller is the general trend.

Compared with traditional silicon wafers, silicon carbide has higher power density, makes the size and volume of the device smaller, and the corresponding battery volume is also smaller, so it can prolong the battery life and make the electric vehicle travel farther.

Globally, the demand for silicon carbide power semiconductors continues to rise. More and more manufacturers are increasing their investment in silicon carbide power semiconductors. Well-known manufacturers include ROHM, Cree, SDK, STMicroelectronics, Littelfuse, Ascatron, Infineon Technologies, etc.

Silicon carbide power semiconductors are extremely efficient, and their advantages are increasingly evident in energy-intensive applications such as e-mobility. In the field of electric vehicle power electronics, the configuration of silicon carbide chips can effectively extend the driving distance on a single charge.

Another large number of its applications are radio frequency RF components. Silicon carbide can have better heat dissipation. Therefore, RF components in 5G base stations are also very suitable for using silicon carbide.