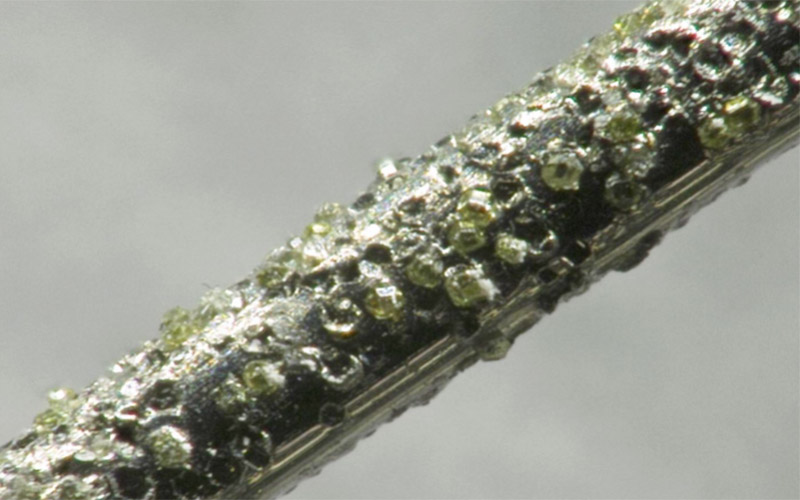

A diamond wire loop is a cutting tool used in various industries for cutting hard materials such as stone, concrete, and metal. It consists of a steel wire embedded with diamond particles along its length. The diamond particles act as the cutting teeth, allowing the wire saw to effectively slice through tough materials.

How is a diamond wire loop made?

Step 1: Steel wire selection – A high-strength steel wire is chosen as the base material for the wire saw. The wire should have good flexibility and durability to withstand the cutting process.

Step 2: Diamond particle embedding – Diamond particles, either natural or synthetic, are carefully and evenly embedded onto the steel wire. This can be done by electroplating, sintering, or using a suitable adhesive. The diamond particles should be securely attached to the wire to ensure their stability during cutting.

Step 3: Wire assembly – The diamond-embedded steel wire is then assembled onto the wire saw machine. The wire is guided by pulleys and tensioned properly to ensure smooth and precise cutting.

Why has diamond wire loop become a new trend in the cutting industry?

The diamond wire loop has become a new trend in the cutting industry due to several factors:

- Superior cutting performance: diamond wire loops offer exceptional cutting performance compared to traditional cutting methods. The diamond particles embedded in the wire provide high hardness and abrasion resistance, allowing for efficient and precise cutting of hard materials. This superior cutting performance translates to increased productivity and reduced production costs.

- Versatility: diamond wire loops can be used to cut a wide range of materials, including natural stone, concrete, metal, and composites. This versatility makes them suitable for various industries, such as construction, mining, and manufacturing. They can handle different shapes, sizes, and thicknesses of materials, providing flexibility in cutting applications.

- Efficiency and speed: diamond wire loops enable faster cutting speeds compared to conventional methods. The continuous cutting action of the wire saw allows for smooth and uninterrupted cutting, resulting in reduced cutting time and increased productivity. This efficiency is especially beneficial for large-scale projects or high-volume production.

- Precision and accuracy: diamond wire loops provide high precision and accuracy in cutting. The thin diamond wire allows for narrow cutting kerfs, minimizing material wastage and enabling precise cuts with tight tolerances. This precision is crucial in industries where accuracy and quality are paramount, such as stone fabrication and aerospace manufacturing.

- Reduced environmental impact: diamond wire loops produce less dust, noise, and vibration compared to other cutting techniques. This not only creates a safer and healthier working environment for operators but also reduces the impact on the surrounding environment. Additionally, the reduced material wastage contributes to sustainable and eco-friendly practices.

- Continuous innovation: The diamond wire looptechnology continuously evolves and improves with advancements in diamond manufacturing, wire design, and cutting machine capabilities. This continuous innovation drives the adoption of diamond wire loops in the cutting industry, as companies seek to stay competitive and achieve better cutting results.

Contact us:

If you have any further inquiries or require more detailed technical support and cooperation information regarding the diamond wire loop technology, please feel free to contact us. We would be more than happy to provide our assistance