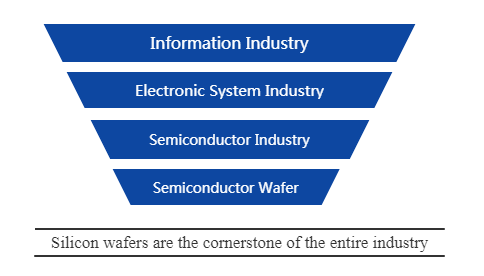

Semiconductor silicon wafer is the upstream of the semiconductor industry chain and the core material for making chips. It runs through the whole process of chip making. The quality and quantity of semiconductor silicon wafers are not only the key materials for making chips, but also restrict the development of the downstream terminal industry.

In the silicon wafer industry chain, the upstream is the raw material silicon mine, the midstream is the silicon wafer manufacturer, and has strong bargaining power, and the downstream is the chip manufacturer.

Upstream silicon mines are rich in raw materials and have weak bargaining power.

In contrast, in the process of silicon wafer production, silicon wafer manufacturers need sophisticated machinery and equipment, mature technological processes and excellent technical personnel to support them in order to produce qualified high-quality silicon wafers.

Therefore, silicon wafer manufacturers’ mastery of machines, technological processes and technical personnel is crucial.

Only silicon wafer manufacturers that meet these conditions have the ability to provide qualified silicon wafers to downstream chip manufacturers.

At the same time, silicon wafers must be certified by downstream chip manufacturers before order transactions can occur.

Therefore, silicon wafer manufacturers that meet customer certification and have higher technical processes have weaker substitutability and stronger bargaining power.

In the semiconductor industry chain, the upstream is mainly the raw materials for chip manufacturing and the key equipment for manufacturing chips, the midstream is the chip manufacturer, and the downstream corresponds to the application manufacturers in the terminal field, such as smartphones, AI and IOT. Upstream wafer raw materials and key equipment have strong bargaining power.

The main reason is that the manufacturing of wafer raw materials and key equipment has high technical barriers and weak substitutability.

The most downstream terminal application fields in the semiconductor industry mainly revolve around: 5G communication, IOT, smart phones, automobiles and AI, etc. The development of these fields drives the demand for semiconductor silicon wafers to rise.

Through the previous analysis, the basis of semiconductor silicon chip manufacturing, and the chip is an indispensable electronic component for terminal applications。

Therefore, the technological innovation of these downstream terminal applications has led to an increase in the demand for midstream chips, thereby promoting the increase in the demand for silicon wafers.

The development of downstream terminals relies on the supply of upstream silicon wafers. Only qualified silicon wafers can lay a solid foundation for the production of chips and provide good chips for downstream terminals.

The purity, surface flatness, cleanliness and impurity contamination of semiconductor silicon wafers have an extremely important impact on the chip, so the manufacture of semiconductor silicon wafers is extremely important.

In the production process of silicon wafers, cropping and cutting are very important in the process of manufacturing silicon wafers.

The cutting of silicon wafers is generally made by diamond long wire cutting. Before cutting, the silicon crystal needs to be cut into small pieces .

The traditional method is cropping with a band saw, which consumes a lot of silicon material. The new process uses a diamond wire loop to cropping, which saves materials and is environmentally friendly.

Compared with the long diamond wire for cutting silicon wafers, the diamond wire loop has a relatively longer diameter and different processing methods. It is mainly used for cropping.

The research and development of new processes has improved the quality and quantity of semiconductor silicon wafers, which is of great help to silicon wafer manufacturers.

When processing silicon wafers, the two diamond wires are used in combination, which saves materials, smoother surface of silicon wafers and faster processing. At present, many large semiconductor companies in China and South Korea have used new processes in silicon wafer processing and chip production.

The video shows the process of silicon cropping:

https://www.youtube.com/watch?v=N57A-9mi-Mk

Contact us to know more !

and here are more interesting applications .