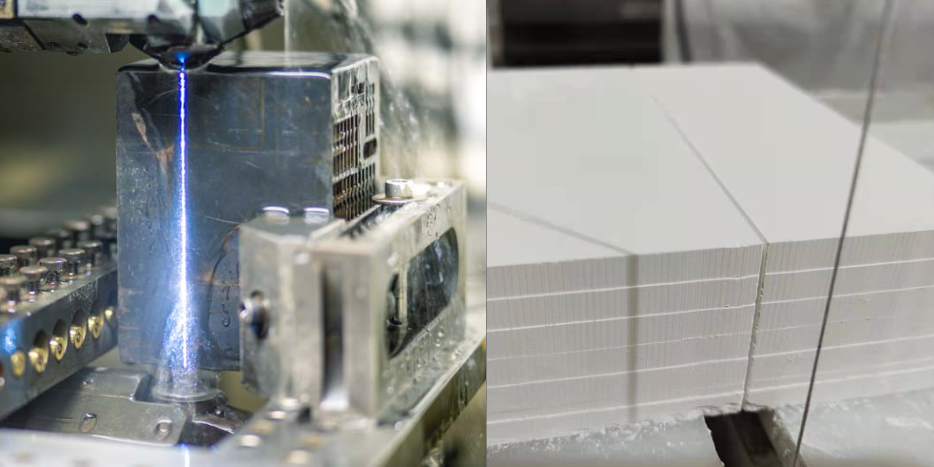

The basic working principle of Wire Electrical Discharge Machining (WEDM for short) is to use continuously moving fine wire (called electrode wire) as electrode to remove metal by pulse spark discharge and cut into shape.It is mainly used to process all kinds of complicated and precise workpieces, such as male die, female die, fixed plate and discharge plate of blanking die, as well as various micro holes, narrow slots, arbitrary curves, etc. It has the advantages of small machining allowance, high machining precision, short production cycle and low manufacturing cost.It has been widely used in production. At present, WEDM machine tools account for more than 60% of the total number of EDM machines.

According to the different running speed of electrode wire, WEDM machine tools are generally divided into two categories: one is high-speed WEDM machine tool, the electrode wire makes high-speed reciprocating motion, the general wire speed is 8-10m/s, the electrode wire can be reused, and the processing speed is high, but the fast wire speed easily causes electrode wire shaking and pause in reverse, which makes the processing quality decline; the other is the low-speed wire cutting machine tool .The electrode wire of low-speed WEDM machine tool moves in a low-speed unidirectional way. Generally, the wire speed is lower than 0.2m/s, and the electrode wire is no longer used after discharge. The work is stable, with small jitter and good processing quality, but the processing speed is too low.

In addition to EDM, there is another method of wire cutting, which is looped diamond wire cutting. This wire is a closed coil, which is coated with diamonds. It uses extremely high linear speed and diamond edges for cutting. Linear speed can reach 60m/s without electricity, which is a very advanced cutting method at present.

https://www.youtube.com/watch?v=wzj-hOMvZUM