How to cut NdFeB magnets?

NdFeB magnets are permanent magnets second only to absolute zero holmium magnets, and they are also the most commonly used rare earth magnets. NdFeB magnets are widely used in electronic products, such as hard drives, mobile phones, headphones, and battery-powered tools. Do you know how to cut NdFeB magnets?

Several processing methods of NdFeB magnets are briefly introduced:

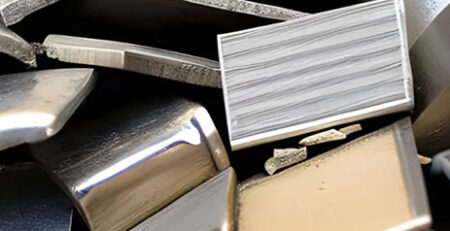

There are basically two types of NdFeB processing: slicer cutting and wire cutting;

First, let’s talk about slicer processing. The slicer is a diamond inner hole cutting blade with a thickness of about 0.3 mm, which can cut the magnet to the desired size as required. However, this method is only suitable for simple square magnet shapes, disc magnet shapes and cylindrical shapes.

Another method is wire cutting. Generally used for cutting NdFeB tiles, special-shaped magnets, and large products.

With the development of technology, a new type of cutting method has emerged. General speaking, the diamond wire loop is an extremely fast closed wire with sharp diamonds on the wire for cutting.

Usually it is very suitable to use a diamond wire loop with a diameter of 0.65 mm to cut NdFeB. Below is the video of our cutting NdFeB:

https://www.youtube.com/watch?v=ZI8z0u4kxys

Contact us to know more !

and here are more interesting applications .