What are the applications of ceramics in new energy vehicles?

Energy shortage, environmental pollution, climate warming and other factors have jointly contributed to the rise of new energy vehicles. The material industry is the cornerstone of modern industry, and in the new energy automobile industry, the application of various advanced materials is also the basis of supporting the entire industry. Here, we will learn about the ceramic materials that are playing an increasingly important role in the intelligent process of new energy vehicles.

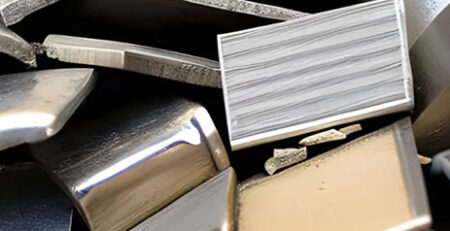

Ceramic substrate

In the core motor drive of new energy vehicles, the use of SiC MOSFET devices will bring 5% to 10% more endurance than the traditional Si IGBT, and will gradually replace the Si IGBT in the future. However, SiC MOSFET chip has small area and high requirements for heat dissipation. Ceramic copper clad plate is a composite material of copper-ceramic-copper “sandwich” structure. It has the characteristics of good heat dissipation, high insulation, high mechanical strength, thermal expansion and chip matching of ceramics, as well as the characteristics of strong oxygen-free copper current carrying capacity, good welding and bonding performance, and high thermal conductivity. It has almost become a necessary option for the application of SiC MOSFET in the field of new energy vehicles.

Silicon nitride ceramic substrate has excellent heat dissipation capability and high reliability, and is one of the key packaging materials for SiC MOSFET modules. It has been used in electric vehicles, aerospace and other fields.

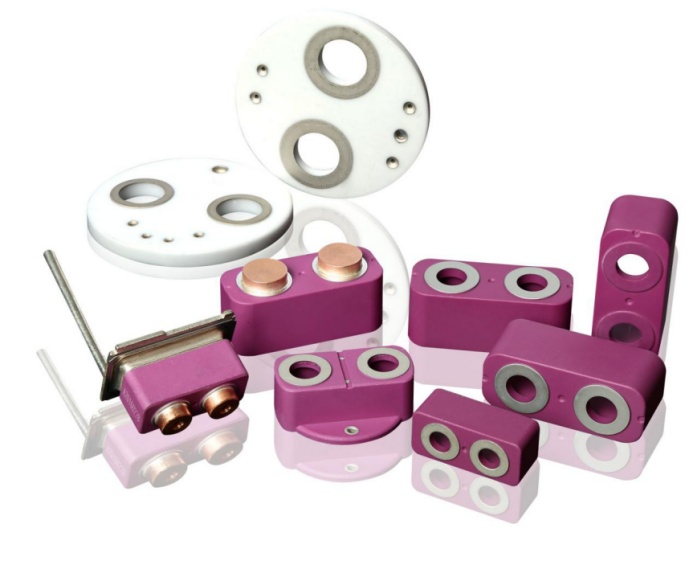

Ceramic relay

Electronic control technology is an important indicator to measure the development level of new energy and energy-saving electric vehicles. High-voltage DC ceramic relay is the core component of the electronic control system. High-voltage DC vacuum relay, in the vacuum chamber sealed by metal and ceramic, the ceramic insulator slides between the moving contact assembly and the push rod, so that the moving contact and the static contact, whether in any state of conduction or disconnection, maintain good electrical insulation with the magnetic circuit system composed of the magnetic yoke iron plate, iron core and other parts of the relay, thus ensuring the arc-breaking ability of the relay when switching DC high-voltage load, Electric arc is the main cause of auto self-ignition. Only relay products with “arc free” connection and disconnection can fundamentally solve the problem of “spontaneous combustion”.

Ceramic fuse

Fuse is a device for overcurrent protection of circuit. During operation, the fuse is connected in series in the circuit, and the load current flows through the fuse. In case of short circuit or overload in the circuit, the thermal effect of overcurrent will melt and vaporize the melt to produce a fracture, and the fracture will produce an arc. The fuse will cut off the fault circuit by extinguishing the arc, thus playing the role of circuit protection.

The fuse for automobile is divided into two parts: low voltage and high voltage. The high voltage protection is mainly applicable to new energy vehicles. The application voltage is generally 60VDC-1500VDC, mainly the power fuse (high voltage fuse for new energy vehicles) to protect the main circuit and auxiliary circuit. As the new energy vehicle market enters the post-subsidy era, personal consumption demand promotes the high voltage platformization of new energy vehicles, and the requirements for safety in the high voltage fields such as fast charging, motor, power device, etc. cannot be ignored. The fast breaking ability of fuse in stability and overcurrent response will maintain the rapid increase of demand under the rapid growth of new energy vehicles.

Chip multilayer ceramic capacitor

Chip multilayer ceramic capacitor (MLCC), known as “electronic industrial rice”, is one of the largest passive electronic components in the world. Almost all consumer electronics use MLCC components. Compared with traditional vehicles, the level of electronization of electric vehicles has been greatly improved. From the new electronic control and battery management systems, from the audio and video entertainment system to the ADAS system to the full auto drive system, the improvement of the level of electronization of automobiles has greatly promoted the growth of MLCC.

Ceramic bearing

In new energy vehicles, the application of ceramic bearings has become a trend. New energy vehicles put forward more new requirements for automobile bearings. First, motor bearings have higher rotational speed than traditional bearings, and require materials with lower density and relatively more wear resistance; At the same time, because the alternating current of the motor causes changes in the surrounding electromagnetic field, better insulation is needed to reduce the electrical corrosion caused by the discharge of the bearing; Third, the bearing ball surface is required to be smoother and less worn. The ceramic ball has the characteristics of low density, high hardness and friction resistance, and is suitable for high-speed rotating conditions. In the fields of high temperature, strong magnetism and high vacuum, the ceramic ball is irreplaceable.

Carbon ceramic brake disc

Carbon ceramic (C/C-SiC) composite is a new type of brake pad material developed on the basis of carbon/carbon composites. The material is composed of quasi-dimensional carbon fiber integral needled felt as the skeleton reinforcement and deposited carbon, SiC and residual silicon as the matrix. This material combines the physical properties of carbon fiber and polycrystalline silicon carbide, and has the characteristics of high temperature stability, high thermal conductivity, high specific heat, etc.

In addition, carbon ceramic brake has the characteristics of lightweight and wear resistance, which not only extends the service life of brake disc, but also avoids all problems caused by load. According to the research, a pair of carbon ceramic brake discs can reduce the weight of the vehicle suspension system by 20kg compared with the same size of gray cast iron brake discs. For electric vehicles, it can increase the driving range by about 50km. Under the trend of electrification, intelligence and high-end in the new energy automobile industry, the carbon ceramic brake system can significantly improve the vehicle response speed and shorten the braking distance, and is expected to become the best actuator for line control, which can be said to be the key weight reduction component of electric vehicles in the future.

Power battery ceramic sealed connector

The ceramic sealed connector of the power battery is an important part of the new energy electric vehicle. It is used to form a sealed conductive connection between the power battery cover plate and the pole in the new energy electric vehicle.

Ceramic has excellent electrical insulation and mechanical strength. It is more and more common to use ceramic seals as seals in the electronic industry. In recent years, leading battery companies have gradually replaced common plastic seals with ceramic seals

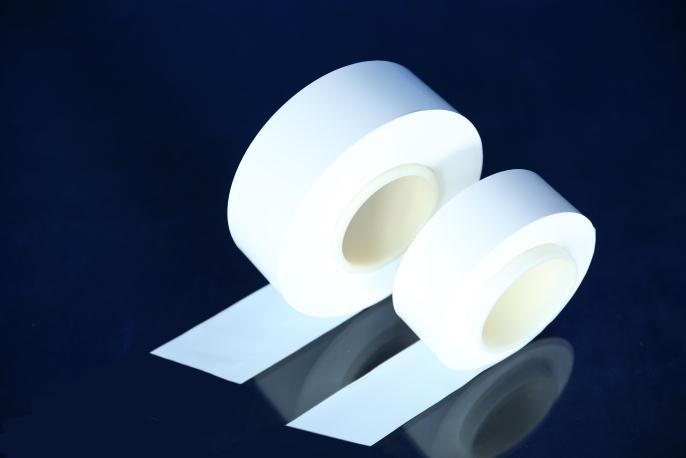

Power battery ceramic diaphragm

Polyolefin membrane is the current mainstream membrane, but its thermal stability is poor. The melting points of polypropylene (PP) and polyethylene (PE) are 165 ℃ and 135 ℃ respectively, which will cause potential safety problems, because at high temperature, the diaphragm will shrink or melt, resulting in internal short circuit, fire and even explosion.

In view of this situation, many methods have been adopted to improve the thermal stability of the diaphragm. Coating a layer of inorganic ceramic particles on the PP or PE diaphragm is considered to be the most effective and economical method. The ceramic material provides high heat resistance, while the adhesive provides adhesion to maintain the structural integrity of the coating and the entire composite diaphragm. On the one hand, due to the improved thermal stability, this ceramic coating diaphragm can effectively improve the safety of lithium ion batteries by preventing short circuit under high temperature; On the other hand, ceramic-coated membrane has good wetting and liquid-absorbing capacity with electrolyte and positive and negative electrode materials, which greatly improves the performance and service life of the battery. Common ceramic materials include α- Alumina, boehmite, SiO2, CeO2, MgAl2O4, ZrO, TiO2, etc.

Optical material

Transparent ceramics refer to polycrystalline materials with certain light transmittance prepared by ceramic technology, also known as optical ceramics. Compared with glass or resin optical materials, transparent ceramic not only has the same light transmission quality as optical glass, but also is stronger, harder, more resistant to corrosion and high temperature, and can be applied to extremely harsh conditions, and the refractive index can change. At present, some manufacturers in the industry have tried to use transparent ceramic materials as vehicle camera lenses, laser radar window materials, laser optical devices, etc