3 minutes to understand optical glass

Optical glass refers to glass that can change the propagation direction of light and change the relative spectral distribution of ultraviolet, visible or infrared light. It is the main material for manufacturing optical lenses and optical instruments. It must have a highly accurate refractive index, Abbe number and high transparency, high uniformity.

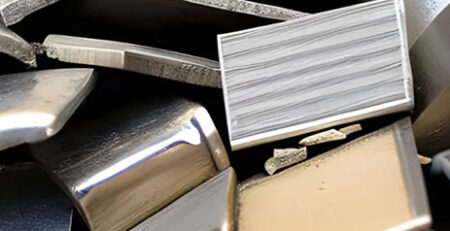

It is made of high-purity silicon, boron, sodium, potassium, zinc, lead, magnesium, calcium, barium and other oxides mixed according to a specific formula, melted at high temperature in a platinum crucible, stirred evenly with ultrasonic waves to remove air bubbles;

Cool down slowly over time to avoid internal stress on the glass block. After cooling, the glass block must be measured by optical instruments to check whether the purity, transparency, uniformity, refractive index and dispersion rate meet the specifications. Qualified glass blocks are heated and forged into optical lens blanks.

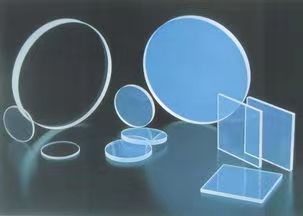

It can be used to manufacture lenses, prisms, mirrors, windows, etc. in optical instruments, and components composed of optical glass are key components in optical instruments.

The Brief History

We can see all kinds of glass in life, such as glass curtain wall, glass cup, car glass and handicrafts. Different from ordinary glass, optical glass is mainly used to manufacture lenses, prisms, mirrors, windows, etc. of optical instruments or mechanical systems.

Archaeologists have proved that people in Egypt and China (Warring States Period) were able to make glass before 3000 AD. But glass as glasses and mirrors started in Venice in the 13th century.

Beginning in the 16th century, due to the development of astronomers and navigation, Galileo, Newton, Descartes, etc. made telescopes and microscopes out of glass.

In the 17th century, achromatism of optical systems became a central problem in optical instruments. Introducing lead oxide in glass, Hull obtained the first achromatic lens in 1729.

In 1768, Jinan first made uniform optical glass by stirring with clay rods in France, and thus began to establish an independent optical glass manufacturing industry.

In the middle of the 19th century, several developed capitalist countries successively established their own optical glass factories, such as Paris-Mantu in France (1872), Chance in England (1848), and Schott in Germany (1848).

It mainly has four key preparation technologies, namely component development, physical and chemical testing, melting process, and melting equipment. Among them, the optical glass melting technology also includes single crucible melting, continuous melting and so on.

From 1953 to 1957, Pilkington and Pickerstaff invented the revolutionary float glass technology, enabling the first continuous production of complete, high-quality glass in the same process.

Then, Japan applied continuous smelting to optical instruments. In 1965, Japan’s HOYA company first realized the continuous melting production of BK7 optical glass without streaks and bubbles. Continuous melting is divided into raw material melting pool, clarifying pool, stirring and homogenizing pool, and finally the leakage material is released.

Processing technology-Cutting

https://www.youtube.com/watch?v=wCB3eZQNhIo

Classification

According to different requirements, optical glass can be divided into three categories: colorless , radiation-resistant, and colored.

Colorless optical glass: It is almost completely transparent in a wide range of visible and near-infrared wavelengths, and is the most widely used optical glass. There are specific requirements for optical constants, and it has the characteristics of high transmission in the visible region and non-selective absorption coloring.

According to the Abbe number, it is divided into coronal glass and flint glass, and each type is divided into several types according to the refractive index, and they are arranged in order according to the refractive index. Mostly used as lenses, prisms, mirrors, etc. for telescopes, microscopes, cameras, etc.

Radiation-resistant optical glass: It has various properties of colorless optical glass, and can basically not change its performance under radioactive irradiation. Under certain γ-ray and X-ray irradiation, the transmittance in the visible area changes less, and the variety and grade are the same as the colorless optical glass. It is mostly used in the manufacture of optical instruments and peep windows under high-energy irradiation.

Colored optical glass: also known as filter glass. It has selective absorption and transmission properties for specific wavelengths in the ultraviolet, visible and infrared regions. According to spectral characteristics, it is divided into three categories: selective absorption type, cut-off type and neutral gray; according to coloring mechanism, it is divided into three categories: ion coloring, metal colloid coloring and sulfur selenide coloring. Mainly used in the manufacture of filters.

It is divided into two categories according to dispersion: coronal (K) with smaller dispersion and flint (F) with larger dispersion.

In recent years, some new types of optical glass have been developed, such as glass with good transmittance to infrared and ultraviolet; glass with extremely high or low refractive index or dispersion; glass that changes color with light intensity; light passes along the direction of magnetic field lines Magneto-optic glass in which the plane of polarization rotates when glass is used; electro-optic glass which produces birefringence under the action of an external electric field, etc.