Corrugated paper overview

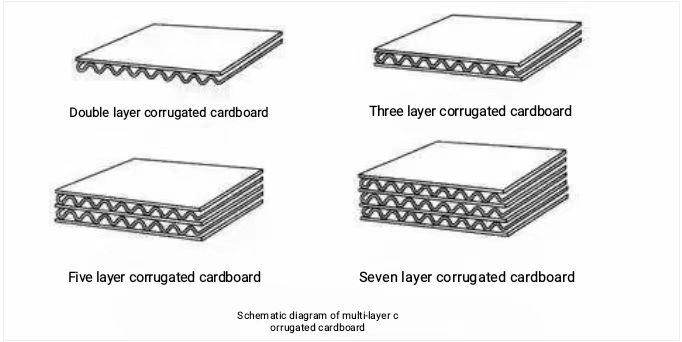

Corrugated paper is a plate-like object formed by bonding liner paper and corrugated corrugated paper formed by corrugating roll processing. Generally divided into single corrugated cardboard and double corrugated cardboard, according to the size of the corrugated is divided into: A, B, C, E, F five types.

The invention and application of corrugated paper has a history of more than 100 years. It has the advantages of low cost, light weight, easy processing, high strength, excellent printing adaptability, and convenient storage and handling.

More than 80% of corrugated paper can be recycled. Corrugated paper can be used as packaging for food or digital products. It is relatively environmentally friendly and widely used.

Corrugated History

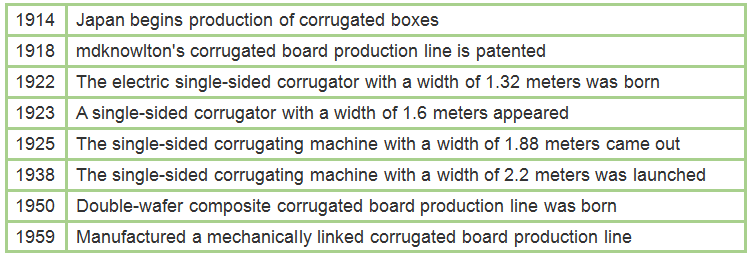

Early development process

In 1856, the English brothers Edward. Healy (edwadciley) and Edward. Allen (edwadellen) pressed the paper into a corrugated corrugated shape as the lining of the hat to breathe and absorb sweat, which is the origin of corrugated paper.

In 1871, American Albert Jones (albertjones) invented single-sided corrugated cardboard for processing cardboard boxes for packaging glass lampshades and similar fragile items, and obtained the first patent right of corrugated paper for packaging in the United States.

In 1874, Oliver Long in the United States started to paste a layer of lining paper on the other side of single-sided corrugated paper to make double-sided corrugated cardboard, and obtained a patent for single-sided corrugated cardboard. Corrugated cardboard has expanded from a single function liner material to the production of corrugated packaging containers.

Design engineer cflangston immigrated from Wales, UK to Philadelphia, USA in 1888, where he opened a machine manufacturing factory. His first design was the shear slitting machine, from which the langston paper roll machine was born.

In 1895, the first slotted corrugated box came out. In the same year, hinde and dauch introduced the patented climax bottle corrugated packaging, which was then used to package glass lampshades for shipping. In 1895, corrugated box packaging began to gain importance in the rail transportation system in the United States.

The rapid development period of corrugated board production line

Since the 1960s, corrugated packaging technology has made great progress, some more advanced technical equipment have been launched one after another, and many high-efficiency and highly automated corrugated cardboard production lines have appeared.

In 1968, a modern corrugated board production line with a width of 2.2 meters and a speed of 212 meters per minute was launched, including a single-sided corrugator without guide jaws and a “double chopper” cross-cutting machine. Since then, the technological progress of the corrugated board production line has entered a period of rapid development.

In the mid-1980s, driven by the two emerging technologies of mechanical design and electronic control, there was a new wave of innovation in the field of tile wire production. These breakthroughs benefit from improvements in the precision and strength of mechanical hardware, as well as breakthrough innovations brought about by new digital electronic controls, stepper motor drives and frequency-controlled AC drives.

At the same time, people have a deeper understanding of the physical and chemical processes in the corrugated process, the reasons for the vibration of the machine and the control inside the machine.

At present, the most advanced corrugated cardboard line in the world, the cardboard processing width is expanded to 2800-3300mm, and the running speed is as high as 375-400m/min. Various types of corrugated cardboard.

The development history of corrugated type

In the more than half a century after the appearance of double corrugated cardboard, the scientific development of corrugated structure has become more perfect and mature. Western corrugated structure technology has only been transmitted to China for only 30 years, and now it has basically reached the modern level.

The first developed flute type is about 4.5 mm high, which is a flute. This type of flute was used in large numbers at the turn of the 19th and 20th centuries. The b flute came out in 1910, and the flute height is about 2.5 mm.

These two flutes were the standard for three-ply and five-ply boards until the 1960s. This alphabetical classification system does not name the corrugated corrugated according to the height of the corrugated pattern.

It was disrupted with the birth of another flute type. The height of the new corrugated type is between a corrugated and b corrugated, and the corrugated height is 3.5 mm, which is called c corrugated.

In the 1960s, E-type corrugated was born. F-type corrugated appeared in the early 1990s, and the remaining corrugated types were also born in the next five or six years.At the end of 2000, the smallest corrugated at that time – O-shaped corrugated came out. So far, ten corrugated types have become the industry’s recognized standard.

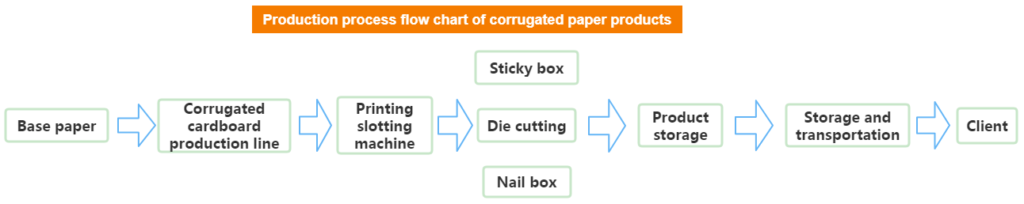

The production process of corrugated paper

The production process of corrugated paper is generally composed of base paper pretreatment, corrugated paper production line board making, printing grooving and subsequent forming of glue box, die cutting and nail box and other processes.

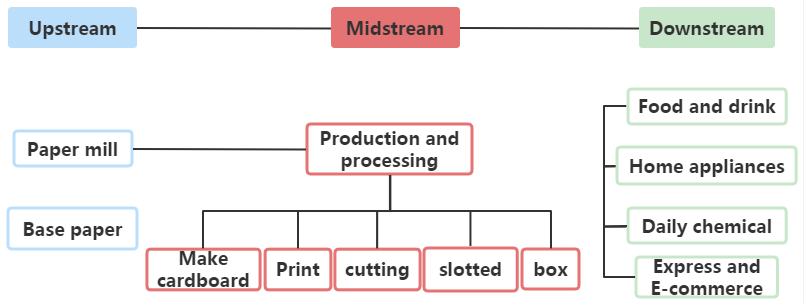

Industry Analysis – Industry Chain Structure

The upstream of corrugated paper is mainly the raw material of base paper provided by paper mills. The production of corrugated paper is in the middle of the industry chain, and the downstream is the packaging application of food and beverage, home appliances, daily chemicals, express delivery and e-commerce.

Corrugated production and processing – cutting

Regarding the corrugated paper cutting process, many manufacturers choose to use diamond wire loop for cutting, the cutting speed is fast and no marks,below the corrugated paper cutting video for reference:

https://www.youtube.com/watch?v=I2pvPcfS87E

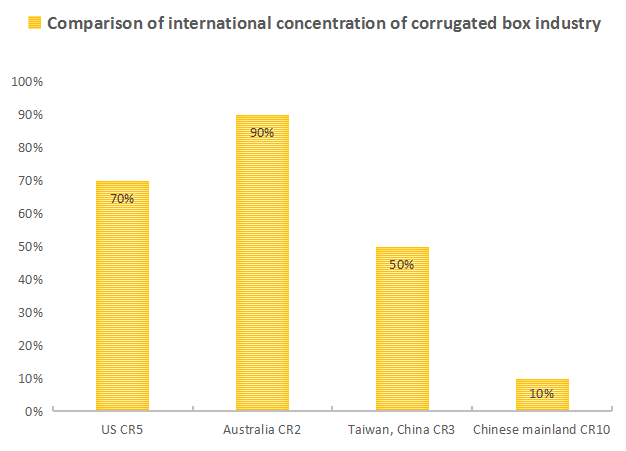

Corrugated paper industry concentration

At present, the top ten corrugated box companies in mainland China have a combined market share of less than 10%, while the top five corrugated box companies in the United States account for about 70% of the domestic market share. In contrast, the concentration of the corrugated box industry in mainland China is low.

With the trend of consumption upgrading in the downstream terminal industry, downstream enterprises will gradually increase their requirements for the quality of corrugated box products and the sophistication of printed content.

At the same time, the increasing environmental protection costs will gradually increase the industry threshold, and corrugated box companies with capital and technical strength will gradually occupy a dominant position in the market.