How Silicon Solar industry make the extremely thin wafer

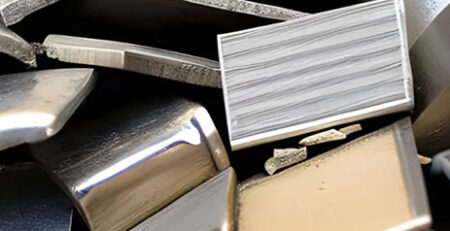

Wafering is the process by which a silicon crystal is made into wafers. This process is usually carried out by a multi wire saw which cuts multiple wafers from the same crystal at the same time. These wafers are then polished to the desired degree of flatness and thickness.

wafering saw (Wafering Machine) is quite important for this industry ,here are main silicon wafer cutting method :

1,Wafering/sectioning blades

Blades is quite common ,it’s like a traditional Saw.but blades that are poorly dressing will tend to push the material, creating high loads, high cutting temperature/heat and poor cut quality. This can also cause blade breakage. Which is extremely dangerous .

2, Wafering /Sectioning Wire Saw

By this diamond cutting tool ,Wafering is typically done using a multi-wire diamond wire saw. A multi-wire saw features a wire that spans many times back and forth across the cutting material. The wire then traverses back and forth over the cutting material to slice thin wafers. The thickness of the wafers is determined by the gaps between spans of wires.

it’s safe and throughput efficiency ,insiders also call it kerfless wafering due to the thin diamond wire saw people use for cutting .

3,Wafering /Sectioning Diamond Wire Loop

Wire loop is more advance than Wire that two ends not connected ,maintaining the safty ,kerfless cutting property ,but enhanced the cutting efficiency by a perpetual rotational movement.

compare to cutting by back and forth movement ,perpetual rotational movement ensures higher speed which conduct cutting activity quicker and gain better cutting surface .