What is Piezoelectric Ceramics

Piezoelectric ceramics refer to polycrystals formed by mixing oxides (zirconia, lead oxide, titanium oxide, etc.) after high-temperature sintering and solid-phase reaction, and making them have piezoelectric effect through DC high-voltage polarization treatment. A general term for ferroelectric ceramics, it is a functional ceramic material that can convert mechanical energy and electrical energy into each other.

Piezoelectric ceramics are a class of electronic ceramic materials with piezoelectric properties. The main difference from typical piezoelectric quartz crystals that do not contain ferroelectric components is that the crystal phases that make up their main components are all ferroelectric grains.

Classification of Piezoelectric Ceramics

According to the main components of the crystal structure, piezoelectric ceramics can be divided into perovskite type, tungsten bronze type, bismuth layered type and pyrochlore type.

According to the types of components, piezoelectric ceramics can be divided into unit systems, binary systems, ternary systems and multi-element systems.

Piezoelectric ceramic preparation process

The preparation process of piezoelectric ceramics used in actual production generally includes several important processes such as batching, ball milling, pre-sintering, molding, plastic removal, sintering, and polarization.

The pre-firing conditions include temperature, heating rate, holding time, temperature uniformity, atmosphere, density of ingredients, etc.;

Plastic discharge conditions include heating rate, holding time, atmosphere;

New molding methods include pressure molding, plastic molding and slurry molding;

The sintering conditions include sintering temperature, heating rate, holding time, cooling rate, cooling method and the like.

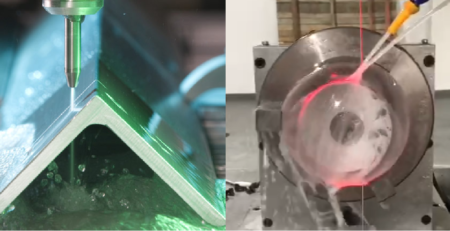

Processing Process of Piezoelectric Ceramics – Cutting

Application of Piezoelectric Ceramics

Piezoelectric ceramics are information-functional ceramic materials that can convert mechanical energy and electrical energy into each other. In addition to piezoelectricity, piezoelectric ceramics also have dielectric properties, elasticity, etc., and have been widely used in medical imaging, acoustic sensors, acoustic transducers, ultrasonic motors, etc.

In addition to being used in high-tech fields, piezoelectric ceramics are also widely used in daily life. For example, there are many friends who smoke around us. Under normal circumstances, they will have a lighter in their pocket. Most of the commonly used lighters are ignited by piezoelectric ceramics through tip discharge.

Generally speaking, the application of piezoelectric ceramics can be divided into frequency control, transducer sensing and optoelectronic devices.

1. Piezoelectric ceramic frequency control device

Piezoelectric frequency control devices include filters, resonators and delay lines, etc. These devices are used in Doubling machines, microcomputers, color TV delay circuits, and the like. Piezoelectric ceramic sheets (piezoelectric vibrators) will generate mechanical vibrations of a certain frequency under the action of an external alternating voltage.

In general, the amplitude of this vibration is small, but when the frequency of the applied voltage is the same as the natural mechanical vibration frequency of the piezoelectric vibrator, resonance will be caused, and the amplitude will be greatly increased. At this time, the alternating electric field generates strain through the inverse piezoelectric effect, and the strain generates current through the positive piezoelectric effect.

Using the characteristics of piezoelectric vibrators, various filters, resonators, etc. can be manufactured, which have good frequency stability, high precision, wide applicable frequency range, small size, no moisture absorption, and long life, especially in multi-channel communication equipment. It can improve the anti-interference performance, so it has replaced a considerable part of electromagnetic oscillators and filters, and this trend is still developing.

2. Piezoelectric transducer

Piezoelectric transducers use the piezoelectric effect and inverse piezoelectric effect of piezoelectric ceramics to realize the mutual conversion of electrical energy and sound energy. Piezoelectric ultrasonic transducer is one of them, which is an underwater acoustic device that transmits and receives ultrasonic waves underwater.

Under the action of sound waves, the piezoelectric transducer in water will induce charges at both ends of the transducer, which is the sound wave receiver; if an alternating electric field is applied to the piezoelectric ceramic sheet, the ceramic sheet will sometimes become thinner Sometimes it thickens, and at the same time, it vibrates and emits sound waves. This is an ultrasonic transmitter.

Piezoelectric transducers are also widely used in water navigation, ocean detection, precision measurement, ultrasonic cleaning, solid flaw detection, medical imaging, ultrasonic diagnosis, and ultrasonic disease treatment in the industry. Another application field of today’s piezoelectric ultrasonic transducers is telemetry and remote control systems, and its specific application examples mainly include piezoelectric ceramic buzzers, piezoelectric igniters, and ultrasonic microscopes.

3. Applications in optoelectronics

In addition to piezoelectric effect, piezoelectric ceramics also have pyroelectric effect, photoelasticity and photoelectric effect. Applications in this regard include: light modulators, light valves, electro-optic displays, optical information storage, image storage and display, and electronically controlled polychromatic filters. Transparent ferroelectric ceramics (PLZT) is a valuable new electronic material, which opens up the development of piezoelectric ceramic materials in electro-optical applications. Wide variable range and low cost.

4. Piezoelectric driver

Piezo actuators are fabricated from the piezoelectric ceramic material lead zirconate titanate (PZT). If a single-plate piezoelectric ceramic PZT is used, a voltage of 5KV needs to be applied to both ends to obtain a driving displacement of about 10 microns for a 1cm-thick PZT. Applying such a high voltage to the PZT may cause the insulation to break down and cause mechanical damage.

Since the amount of deformation of piezoelectric ceramics is independent of thickness, a stacked piezoelectric actuator has been developed. The piezoelectric ceramics are made into very thin sheets (0.05 mm piezoelectric ceramic sheets can be produced now), and multiple piezoelectric ceramic substrates are connected in series mechanically, in parallel on the circuit, and then sintered together.

In this way, a large drive displacement can be obtained by applying a voltage of several hundred volts to it. In applications, flexible hinge structures with small volume, no mechanical friction, no clearance, and high motion sensitivity have also been developed for displacement amplification.

5. Micro locator

Micro-positioners are mainly used for positioning control with micron and sub-micron precision, such as the production of optical instruments, optical fiber docking, high-precision three-dimensional micro-moving tables, high-precision machining and research on tunnel effects.

In positioning technology, traditional positioning devices, such as rolling or sliding guide rails, precision helical wedge mechanisms, turbine-cam mechanisms, gear-lever mechanisms and other mechanical transmission micro-displacement drives constitute the positioning mechanism, due to the existence of large gaps and friction, so ultra-precise positioning cannot be achieved.

The use of piezoelectric actuators combined with flexible hinge amplification mechanisms can overcome the above shortcomings and achieve ultra-precision positioning at the micro-nano level.

6. Ultrasonic motor

Ultrasonic motor is a new type of motor, which is driven by piezoelectric ceramic materials. Under the alternating electric field, the ceramic produces a stretching phenomenon. When a certain type of ultrasonic frequency vibration and fluctuation is excited in the elastic body, the surface of the elastic body pushes the object in contact with it with the help of friction force.

Usually through the conversion and recombination of various vibration modes, the piezoelectric motor can convert the simple stretching mode of the piezoelectric body into the required driving mode that can be used to generate rotational or linear motion.

7. Active vibration control

Active vibration control utilizes the intelligent function of piezoelectric ceramics (piezoelectric ceramics can not only sense noise signals, but also send out acoustic signals with opposite phases and equal intensity to the noise signal to cancel the noise function), it is mainly used in aircraft, diving Active noise control of boats and military vehicles is a very useful high-tech and will play an important role in the future military field.

8. Ultrasound medical treatment

The most widely used piezoelectric ultrasonic medical instrument is the B-type ultrasonic diagnostic instrument. The ultrasonic generating probe made of piezoelectric ceramics is used in this diagnostic instrument.

The ultrasonic waves emitted by it are transmitted in the human body, and various tissues in the body have different reflection and transmission effects on the ultrasonic waves. The reflected ultrasonic waves are converted into electrical signals by the piezoelectric ceramic receiver, and displayed on the screen, according to which the position, size and the presence or absence of lesions of each internal organ can be seen. B-type ultrasonography is usually used to check visceral diseased tissue (such as mass, etc.).

Piezoelectric ceramics can also be used in ultrasound therapy. When the ultrasonic wave entering the human body reaches a certain intensity, it can make a certain part of the human body heat up and vibrate slightly, which can play the role of massage and massage, and achieve the purpose of treatment, such as the treatment of joints, muscles and other soft tissue trauma and strain. In addition, ultrasound can also be used to crush body stones, such as gallstones, kidney stones, urinary tract stones, etc.

In short, as the main functional material in modern industrial production, piezoelectric ceramics are favored by many high-tech industries, such as electronic technology, aerospace, biological research, etc. It is believed that with the improvement of the relevant technical level, the quality of piezoelectric ceramic materials will be further improved and applied in more industries, promoting the development of materials through their own advantages.