Application of foam ceramics

Foam ceramic is a kind of porous material, which is the third generation of porous ceramic products developed after the first generation of ordinary porous ceramics and the second generation of honeycomb porous ceramics.

Its pore size ranges from nanometer to micrometer, and has the characteristics of three-dimensional network structure and high porosity, and the porosity can reach more than 90%.

It has the advantages of light weight, high porosity, large specific surface area, thermal shock resistance, corrosion resistance, high temperature resistance, long service life and good filtration and adsorption.

The development of the third generation of foamed ceramic materials began in the 1970s. As a new type of inorganic non-metallic filter material, it is mainly made of raw ore powder, kaolin, or ceramic industrial waste, fly ash, coal gangue, and marble tailings.

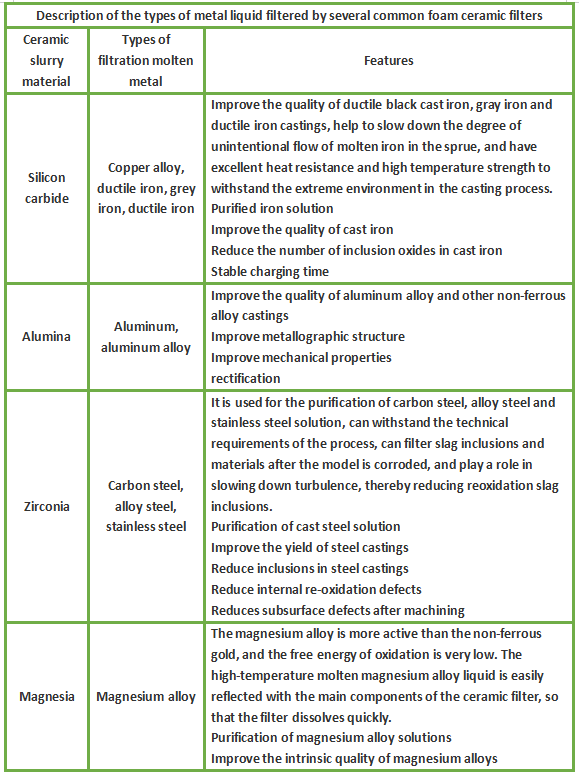

Inorganic materials such as slag and slag are used as raw materials, and a certain proportion of foaming agents, co-solvents, etc. are added to make water-based ceramic slurry, which is impregnated on the foam to form a ceramic film coating, and then fired. According to the molten metal object to be filtered, common materials are silicon carbide, alumina, zirconia, magnesia, etc.

At present, foamed ceramics have been widely used in many fields. In addition to purifying metallurgical industry and filtering molten metal, they are also used in thermal insulation and sound insulation materials, chemical catalyst carriers and other applications.

For example, Jiangxi Longfa Industry recently recycled and reused waste ceramics as raw materials to make ceramic permeable bricks, so as to realize the sustainable development and reuse of local ceramic wastes.

一: Purify metallurgical industry to filter molten metal

Foam ceramic filters are mainly used in casting processes to purify liquid casting alloys and reduce or eliminate various non-metallic inclusions and exhaust problems in castings. Casting scraps caused by casting defects such as non-metallic inclusions account for up to 50%-60% of the total number of scraps.

At the same time as various costs increase, the outflow of excess scraps can cause damage to the external environment. It seriously drags down the mechanical properties and casting properties of the casting, and also has a detrimental effect on the machining and appearance of the casting.

In order to solve this problem, people initially used barbed wire, perforated steel plates, etc., to insert simple filters into the casting system to remove inclusions; to silicate pin fibers, boron nitride fibers and other two-dimensional structures.

Nowadays, the foam ceramic filter uses the pore size to mechanically intercept the large particle inclusion oxide, and uses the filter cake to filter the small particle inclusion oxide. And with adsorption and rectification capabilities, the production line using foam ceramic filters has significantly improved the yield of castings.

For example, after using the foam ceramic filter in Dongfeng Motor Foundry No. 2, the yield increased from 65.3% to 71.5%, and the molten iron was saved by 6% only from the weight of the pouring riser. Filtered castings are also significantly harder, which in turn extends the life of the cutting tool.

Foam ceramic filters generally use polyurethane foam as a carrier, immersed in a ceramic slurry made of refractory aggregate sintering aids, binders and other micropowders plus water, and then extruded excess slurry, and the rest is wrapped in The ceramic material around the foam fiber is dried, fired and sintered at a high temperature, and finally the foam-like ceramic product is left.

Due to the different pouring temperature of the casting alloy, the foam ceramic filter of the refractory material should be selected differently for the casting. In recent decades, according to the properties of different material alloys, a variety of material foam ceramic filters have been developed.

二: heat insulation and sound insulation materials on environmentally friendly buildings

As a new low-cost green energy-saving and environmentally friendly product, energy-saving thermal insulation foam ceramics mainly use waste fly ash, slag, waste glass, ceramic flakes, clay, feldspar tailings, etc. as raw materials.

Metal material has excellent characteristics such as fire prevention, waterproof, antifreeze, anti-moth, anti-magnetic wave static electricity, sound insulation and noise reduction, low thermal conductivity and good adhesion with various types of mud. Blocks, lime-sand bricks, red bricks and other building wall materials have high-quality thermal insulation and waterproof performance, and the construction speed is fast, the difficulty is low, the cost is moderate, and the working hours are low.

2.1 Foam ceramic sound absorption and noise reduction material

The complicated living environment in big cities brings a series of noise problems, which will have a great impact and harm on people’s hearing, sleep, physical and psychological aspects. It plays a big role in construction. The foam ceramic has a large number of pores with a three-dimensional spatial network structure.

After the sound wave is introduced into the porous interior, it will cause the air in the pores to vibrate and rub at the ribs in the foam ceramic. So as to achieve the effect of sound absorption and noise reduction.

Foam ceramics used as sound absorption and noise reduction materials have the following advantages:

1. Light weight, high strength, excellent medium and low frequency sound absorption, durable, safe and reliable, flexible structure, easy construction and installation;

2. At the same time, it is suitable for use in high temperature and humid environment. Even if it is subjected to wind, sun and rain all year round, it will not change its own mesh structure and sound absorption performance;

3. Can well absorb the reverberation sound caused by reflection;

4. It has good fire resistance and high cost performance.

The current applications of foamed ceramics as sound-absorbing materials include installation in the middle of automobile exhaust pipes to reduce noise there. Some new green buildings also use foamed ceramics as wall materials, thereby achieving excellent sound insulation effects. Some developed countries, such as the United States, Japan and Germany, use new foam ceramics to build viaducts and highways as noise and noise barriers.

2.2 Foam ceramic thermal insulation materials

The high porosity and low thermal conductivity of the matrix make the foam ceramics have the characteristics of low thermal conductivity and good thermal shock resistance, which can be used in various occasions to prevent heat radiation, heat preservation and energy saving.

The building materials prepared by using foamed ceramics can make the house have excellent thermal insulation effect, so that the air conditioner in summer and the heating in winter can be well preserved indoors and not easy to disperse.

In terms of building fire protection function, the foamed ceramic does not burn, its expansion coefficient is similar to that of metal materials, and the difference between expansion and contraction is relatively small, which can avoid the risk of shelling of the insulation material and the wall material caused by the difference in expansion and contraction, and ensure the airtightness of the insulation structure.

At present, several advanced building materials have been applied in some new residential quarters and office buildings in China. In addition, foam ceramic materials play an important role in the aerospace field. For example, the thermal protection system of spacecraft is widely used in this material.