3 minutes to understand lithium niobate crystal(1)

With the introduction of “new infrastructure”, 5G has gradually entered our lives, and services such as cloud computing, virtual reality, data communication, and high-definition video have also continued to develop, driving the upgrade of core optical networks to ultra-high-speed and ultra-long-distance transmission. In this process, there is a core device that is essential – that is the lithium niobate modulator (LiNbO3).

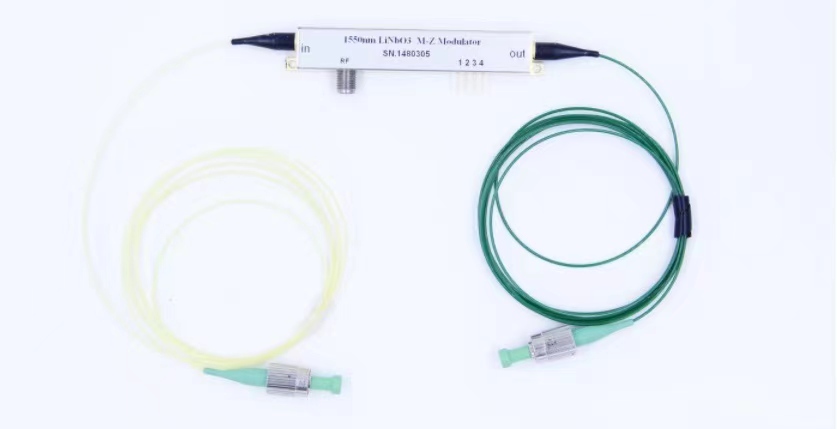

Lithium Niobate Modulator

It is reported that the lithium niobate modulator is made by using the electro-optic effect of lithium niobate crystal combined with the optoelectronic integration process. It can convert electronic data into photonic information and is the core component for realizing electro-optical conversion. Specifically, what is outstanding about it, we must first understand the electro-optical effect and application of its raw material lithium niobate crystal.

About lithium niobate crystals

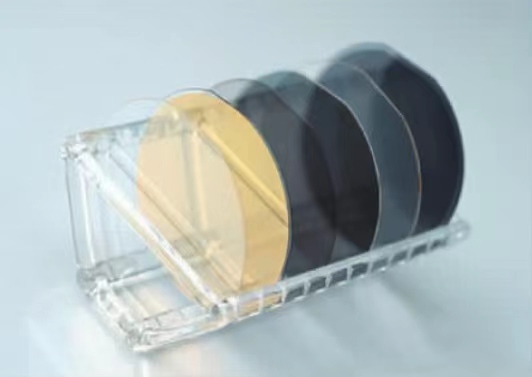

Lithium niobate is a compound of niobium, lithium and oxygen. It is a negative crystal with a large spontaneous polarization (0.70 C/m2 at room temperature), and is a ferroelectric with the highest Curie temperature (1210 °C) found so far.

The picture on the left is a 3-inch optical grade nominally pure lithium niobate crystal with the same composition; the picture on the right is an iron-doped lithium niobate crystal

Lithium niobate crystals have two characteristics that are particularly attractive. First, lithium niobate crystals have many photoelectric effects, including piezoelectric effect, electro-optic effect, nonlinear optical effect, photorefractive effect, photovoltaic effect, and photoelastic effect, acousto-optic effect and other photoelectric properties;

Second, the performance of lithium niobate crystals is highly controllable, which is caused by the lattice structure and abundant defect structures of lithium niobate crystals. Many properties of lithium niobate crystals can be greatly regulated by crystal composition, element doping, and valence control.

In addition, the physical and chemical properties of lithium niobate crystals are quite stable, easy to process, wide light transmission range, large birefringence, and easy to prepare high-quality optical waveguides.

Therefore, the optical modulator based on lithium niobate crystal has unparalleled advantages in long-distance communication: it not only has a small chirp effect, high modulation bandwidth, good extinction ratio, but also has excellent stability and high speed. It is widely used in high-speed and high-bandwidth long-distance communication.

Harvard University once commented on lithium niobate: if the center of the electronic revolution is named after silicon material, then the birthplace of the photonics revolution is likely to be named after lithium niobate.

Preparation of Lithium Niobate Crystals

(1) Lithium niobate crystal with the same composition

For the same composition of lithium niobate crystal, its preparation mainly adopts the pulling method. Although the bubble method, the guided mode method, and the temperature gradient method have also been used to prepare lithium niobate crystals, they have no obvious advantages or clear application requirements compared with the pulling method, so they have not received extensive attention.

(2) Near stoichiometric ratio of lithium niobate crystals

Although the near-stoichiometric ratio lithium niobate crystal has many excellent photoelectric properties, its ratio deviates from the eutectic point of the solid-liquid and the same composition, so it is impossible to use the conventional pulling method to grow high-quality crystals. At present, the main preparation methods are lithium-rich melt method, flux method and diffusion method.

(3) Lithium niobate single crystal thin film

Lithium niobate single crystal thin films can be used in micro-nano structures such as optical waveguides and acoustic devices, as well as in the preparation of hybrid integrated devices such as silicon-based devices. People have been exploring the preparation of lithium niobate single crystal thin films for a long time, but the only method that has really been applied is the “Ion Slicing” technology. At present, it has been commercialized and can provide single crystal thin film products with a thickness of 300~900 nm.

Lithium niobate single crystal thin film

The article is not over yet, please read Article 2