Mikä on safiiri

Safiiri is a precious jalokivi, erilaisia mineraalikorundia, joka koostuu alumiinioksidista (α-Al203) pieniä määriä alkuaineita, kuten rautaa, titaani, kromi, vanadiini, tai magnesium. Nimi safiiri on johdettu latinan kielestä “safiiri” ja kreikkalainen “safiirit”, both of which mean blue.

It is typically blue, but natural “fancy” sapphires also occur in yellow, purple, orange, and green colors; “parti sapphires” show two or more colors. Red corundum stones also occur, but are called rubies not sapphires.

Pink-colored corundum may be classified either as ruby or sapphire depending on locale. Commonly, natural sapphires are cut and polished into gemstones and worn in jewelry. They also may be created synthetically in laboratories for industrial or decorative purposes in large crystal boules.

Because of the remarkable hardness of sapphires – 9 on the Mohs scale (the third hardest mineral, after diamond at 10 and moissanite at 9.5) – sapphires are also used in some non-ornamental applications, such as infrared optical components, high-durability windows, wristwatch crystals and movement bearings, and very thin electronic wafers, which are used as the insulating substrates of special-purpose solid-state electronics such as integrated circuits and GaN-based blue LEDs.

Natural sapphires

Safiiri is one of the two gem-varieties of corundum, the other being ruby (defined as corundum in a shade of red). Although blue is the best-known sapphire color, they occur in other colors, including gray and black, and also can be colorless. A pinkish orange variety of sapphire is called padparadscha.

Significant sapphire deposits are found in Australia, Afghanistan, Cambodia, Cameroon, Kiina (Shandong), Colombia, Ethiopia, India (Kashmir), Kenya, Laos, Madagascar, Malawi, Mozambique, Myanmar (Burma), Nigeria, Rwanda, Sri Lanka, Tanzania, Thailand, Yhdysvallat (Montana) and Vietnam. Sapphire and rubies are often found in the same geographical settings, but they generally have different geological formations. Esimerkiksi, both ruby and sapphire are found in Myanmar’s Mogok Stone Tract, but the rubies form in marble, while the sapphire forms in granitic pegmatites or corundum syenites.

Every sapphire mine produces a wide range of quality, and origin is not a guarantee of quality. For sapphire, Kashmir receives the highest premium, although Burma, Sri Lanka, and Madagascar also produce large quantities of fine quality gems.

The cost of natural sapphires varies depending on their color, clarity, koko, cut, and overall quality. Sapphires that are completely untreated are worth far more than those that have been treated. Geographical origin also has a major impact on price. For most gems of one carat or more, an independent report from a respected laboratory such as GIA, Lotus Gemology, or SSEF, is often required by buyers before they will make a purchase.

Colors

Sapphires in colors other than blue are called “fancy” tai “parti-colored” sapphires.Fancy sapphires are often found in yellow, orange, green, brown, purple and violet hues.

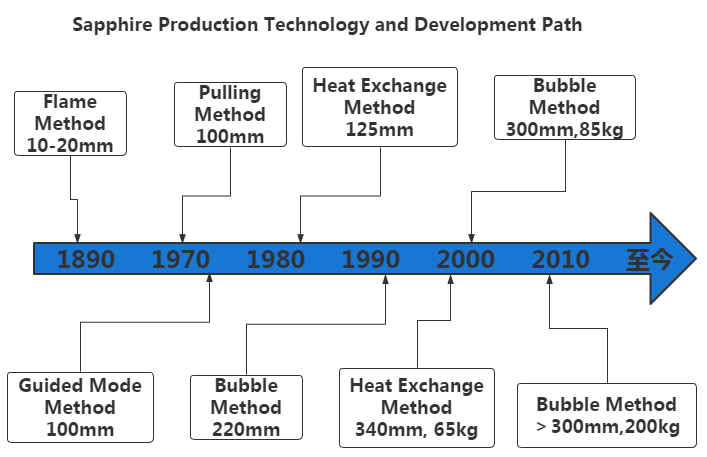

Synthetic sapphire

Sisään 1902, the French chemist Auguste Verneuil announced a process for producing synthetic ruby crystals. In the flame-fusion (Verneuil process), fine alumina powder is added to an oxyhydrogen flame, and this is directed downward against a ceramic pedestal. Following the successful synthesis of ruby, Verneuil focussed his efforts on sapphire. Synthesis of blue sapphire came in 1909, after chemical analyses of sapphire suggested to Verneuil that iron and titanium were the cause of the blue color. Verneuil patented the process of producing synthetic blue sapphire in 1911.

The key to the process is that the alumina powder does not melt as it falls through the flame. Instead it forms a sinter cone on the pedestal. When the tip of that cone reaches the hottest part of the flame, the tip melts. Thus the crystal growth is started from a tiny point, ensuring minimal strain.

Seuraava, more oxygen is added to the flame, causing it to burn slightly hotter. This expands the growing crystal laterally. Samaan aikaan, the pedestal is lowered at the same rate that the crystal grows vertically. The alumina in the flame is slowly deposited, creating a teardrop shaped “boule” of sapphire material. This step is continued until the desired size is reached, the flame is shut off and the crystal cools. The now elongated crystal contains a lot of strain due to the high thermal gradient between the flame and surrounding air. To release this strain, the now finger-shaped crystal will be tapped with a chisel to split it into two halves.

Due to the vertical layered growth of the crystal and the curved upper growth surface (which starts from a drop), the crystals will display curved growth lines following the top surface of the boule. This is in contrast to natural corundum crystals, which feature angular growth lines expanding from a single point and following the planar crystal faces.

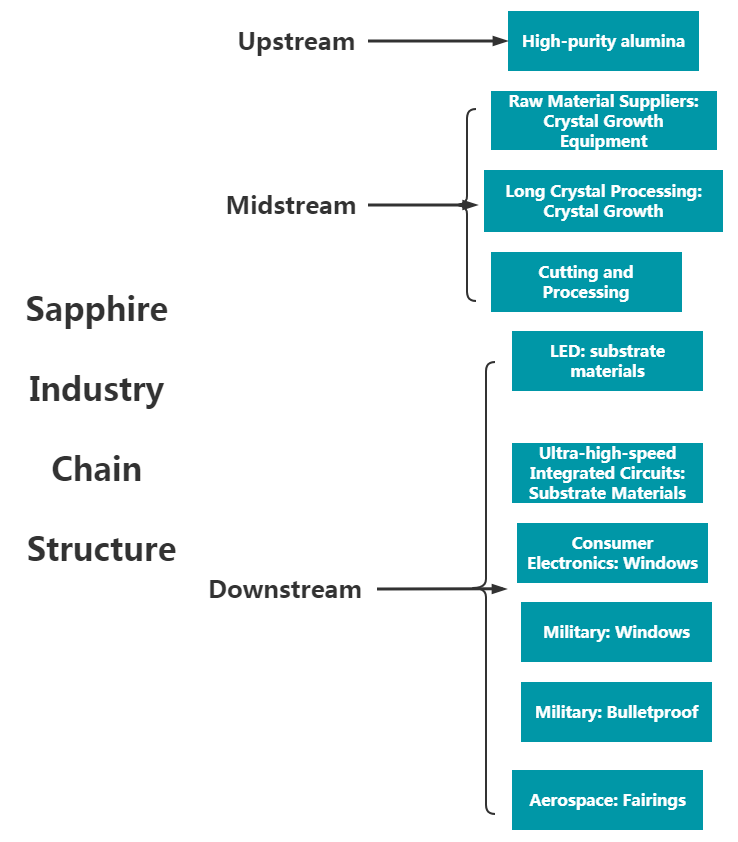

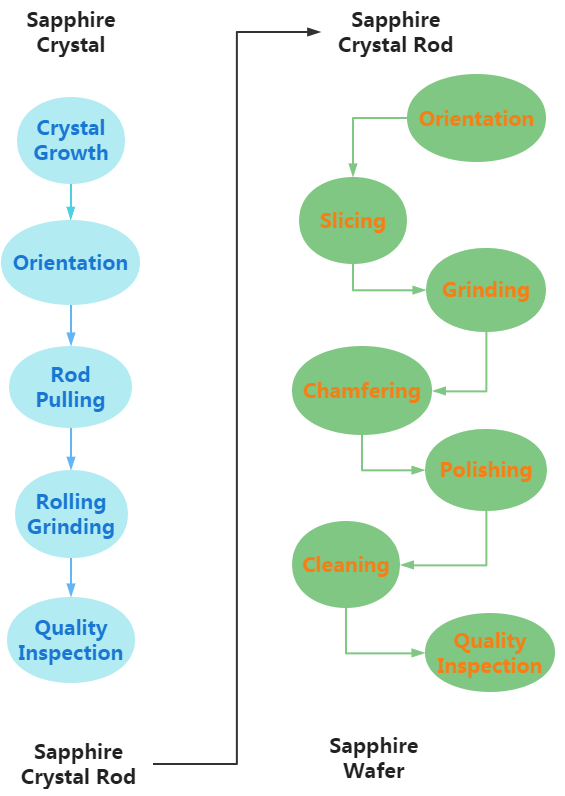

The raw material of the safiiri substrate is a crystal rod, and the crystal rod is processed from a sapphire crystal. The related manufacturing process is as follows; the cultivation of the crystal rod is the most critical in the sapphire substrate manufacturing process.

Sovellukset

1.window

Synthetic safiiri—sometimes referred to as sapphire glass—is commonly used as a window material, because it is both highly transparent to wavelengths of light between 150 nm (UV) ja 5500 nm (IR) (the visible spectrum extends about 380 nm to 750 nm), and extraordinarily scratch-resistant.

The key benefits of safiiri windows are:

1.Very wide optical transmission band from UV to near-infrared, (0.15–5.5 µm)

2.Significantly stronger than other optical materials or standard glass windows

3.Highly resistant to scratching and abrasion (9 on the Mohs scale of mineral hardness scale, the 3rd hardest natural substance next to moissanite and diamonds)

4.Extremely high melting temperature (2030 °C)

Single crystal sapphire boule grown by the Kyropoulos method. Approximately 200 millimetres (8 sisään) in diameter, weighing approximately 30 kg (66 lb).

Some sapphire-glass windows are made from pure sapphire boules that have been grown in a specific crystal orientation, typically along the optical axis, the c-axis, for minimum birefringence for the application.

The boules are sliced up into the desired window thickness and finally polished to the desired surface finish. Sapphire optical windows can be polished to a wide range of surface finishes due to its crystal structure and its hardness. The surface finishes of optical windows are normally called out by the scratch-dig specifications in accordance with the globally adopted MIL-O-13830 specification.

The safiiri windows are used in both high pressure and vacuum chambers for spectroscopy, crystals in various watches, and windows in grocery store barcode scanners since the material’s exceptional hardness and toughness makes it very resistant to scratching.

Sisään 2014 Apple consumed “one-fourth of the world’s supply of sapphire to cover the iPhone’s camera lens and fingerprint reader.”

Several attempts have been made to make sapphire screens for smartphones viable. Apple contracted GT Advanced Technologies, Inc. to manufacture sapphire screens for iPhones, the venture failed resulting in the bankruptcy of GTAT. The Kyocera Brigadier was the first production smartphone to feature a sapphire screen.

It is used for end windows on some high-powered laser tubes as its wide-band transparency and thermal conductivity allow it to handle very high power densities in the infrared or UV spectrum without degrading due to heating.

Along with zirconia and aluminum oxynitride, synthetic sapphire is used for shatter resistant windows in armored vehicles and various military body armor suits, in association with composites.

One type of xenon arc lamp – originally called the “Cermax” and now known generically as the “ceramic body xenon lamp” – uses sapphire crystal output windows. This product tolerates higher thermal loads and thus higher output powers when compared with conventional Xe lamps with pure silica window

2. As substrate for semiconducting circuits

Thin sapphire wafers were the first successful use of an insulating substrate upon which to deposit silicon to make the integrated circuits known as silicon on sapphire or “SOS”; now other substrates can also be used for the class of circuits known more generally as silicon on insulator. Besides its excellent electrical insulating properties, sapphire has high thermal conductivity. CMOS chips on sapphire are especially useful for high-power radio-frequency (RF) applications such as those found in cellular telephones, public-safety band radios, and satellite communication systems. “SOS” also allows for the monolithic integration of both digital and analog circuitry all on one IC chip, and the construction of extremely low power circuits.

In one process, after single crystal sapphire boules are grown, they are core-drilled into cylindrical rods, and wafers are then sliced from these cores.

Wafers of single-crystal sapphire are also used in the semiconductor industry as substrates for the growth of devices based on gallium nitride (GaN). The use of sapphire significantly reduces the cost, because it has about one-seventh the cost of germanium. Gallium nitride on sapphire is commonly used in blue light-emitting diodes (LEDs).

3. In lasers

The first laser was made in 1960 by Theodore Maiman with a rod of synthetic ruby. Titanium-sapphire lasers are popular due to their relatively rare capacity to be tuned to various wavelengths in the red and near-infrared region of the electromagnetic spectrum. They can also be easily mode-locked. In these lasers a synthetically produced sapphire crystal with chromium or titanium impurities is irradiated with intense light from a special lamp, or another laser, to create stimulated emission.

4. In endoprostheses

Monocrystalline sapphire is fairly biocompatible and the exceptionally low wear of sapphire–metal pairs has led to the introduction (in Ukraine) of sapphire monocrystals for hip joint endoprostheses