Johdanto:

Autoteollisuudessa, Rengasosan leikkaus on kriittinen tarkastusprosessi, korjaus, ja käyttökelpoisten osien pelastaminen. Tarkkojen ja tehokkaiden leikkausten tekemiseen, käytetään erikoisleikkaustyökalua, joka tunnetaan nimellä rengasosan leikkauslanka. Tämä leikkaustyökalu käyttää timanttilankasilmukkaa, eräänlainen monisäikeinen lanka, saavuttaaksesi puhtaat ja tasaiset leikkaukset renkaissa. Tässä blogikirjoituksessa, we will explore the features and benefits of the tire section cutting wire and highlight its cutting process and results.

Features and Benefits of the Renkaan § Leikkauslanka:

The tire section cutting wire is designed with several features that make it an ideal tool for tire cutting applications. Some of its notable features include:

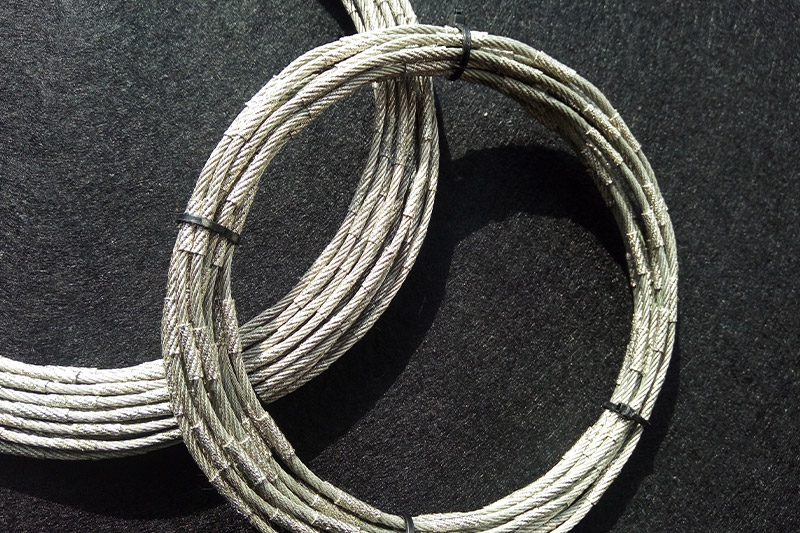

- Timanttilanka Loop: The cutting wire is constructed with a diamond wire loop, which consists of multiple strands embedded with diamond particles. This composition ensures high hardness and abrasion resistance, enabling the wire to easily penetrate through the rubber material of the tire.

- Multi-strand Wire: The tire section cutting wire is made up of multiple strands, which enhance its strength and durability. This allows for prolonged and continuous cutting without the risk of wire breakage.

- High Linear Velocity: The cutting wire operates at a linear velocity ranging from 30-60 neiti. This high speed ensures efficient and swift cutting, reducing the overall cutting time and increasing productivity.

- Adjustable Feed Speed: The feed speed, which ranges from 5-100 mm / min, can be adjusted according to the specific requirements of the cutting process. This flexibility allows for precise control over the cutting depth and ensures optimal results.

- Dry Cooling: The tire section cutting wire employs a dry cooling method, eliminating the need for additional coolant or water. This not only simplifies the cutting process but also reduces the risk of contamination and corrosion.

Cutting Process and Results:

To provide a clear understanding of the tire section cutting wire’s effectiveness, let’s consider a practical cutting scenario. For instance:

lineaarinen nopeus: 35 neiti

syöttönopeus: 50 mm / min

jäähdytys Way: Kuiva

Vetolujuus: 130N

Under these cutting parameters, the tire section cutting wire delivers outstanding results:

Clear and Smooth Cutting Surface: The cutting wire achieves a clean and smooth cutting surface, ensuring precise and accurate cuts on the tire. Even sections with steel wire are cut off flat, eliminating the need for secondary grinding or refinement.

No Secondary Grinding Required: Thanks to the tire section cutting wire’s exceptional cutting performance, there is no need for additional grinding or polishing after the cutting process. This saves time and effort, streamlining the overall tire section cutting operation.

Conclusion:

The tire section cutting wire, equipped with a diamond wire loop and multi-strand construction, offers a highly efficient and precise solution for cutting tires in the automotive industry. Its distinctive features, such as high linear velocity, adjustable feed speed, and dry cooling method, contribute to seamless and effective cutting operations. With clear and smooth cutting results, the tire section cutting wire eliminates the need for secondary grinding, enhancing productivity and efficiency in tire repair and salvage processes.