Kovuuden esittely, alumiinioksidin teollisuuskeramiikan luokittelu ja leikkaus

1.Introduction to the hardness of alumina industrial ceramic

The hardness of alumina industrial ceramic is extremely high. Olipa kyseessä monikiteinen alumiinioksidin teollisuuskeramiikka tai yksikidealumiinioksiditeollinen keramiikka, siinä on korkea ruostumattoman teräksen kovuus.

Keraamisten kannattimien kovuudesta johtuen, se voi olla yli yhdeksän kertaa suurempi kuin ruostumaton teräs ja emali. Joten kun hampaamme ovat kosketuksissa keraamisten kiinnikkeiden kanssa, the enamel will be worn away in a very short period of time.

Alumina Ceramic

2.Introduction to the classification of alumina industrial ceramics

Alumina industrial ceramics are divided into high-purity type and general type. High-purity alumina industrial ceramics are ceramic materials with an alumina content of more than 99.9%.

Because its sintering temperature is as high as 1650-1990 ℃, and the transmission wavelength is 1~6 μm, it is generally made into molten glass to replace platinum crucible, and its light transmittance and alkali metal corrosion resistance are used as sodium lamps.

In the electronics industry, it can be used as an integrated circuit substrate and a high-frequency insulating material. The general alumina industrial ceramics are divided into 99 keramiikka, 95 keramiikka, 90 keramiikka, 85 ceramics and other types according to different alumina contents.

Sometimes those with alumina content of 80% tai 75% are also classified as general alumina industrial ceramics series, among which 99 alumina ceramic materials are used to manufacture high temperature crucibles, refractory furnace tubes and special wear-resistant materials.

Such as ceramic bearings, ceramic seals and water valve plates, jne.; 95 alumina ceramics are mainly used as corrosion-resistant and wear-resistant parts, ja 85 ceramics are often mixed with some talc, which improves electrical performance and mechanical strength.

It can be sealed with molybdenum, niobium, tantalum and other metals, and some are used as electric vacuum equipment. The skills of alumina industrial ceramics are becoming more and more sophisticated, but some goals still need to be improved.

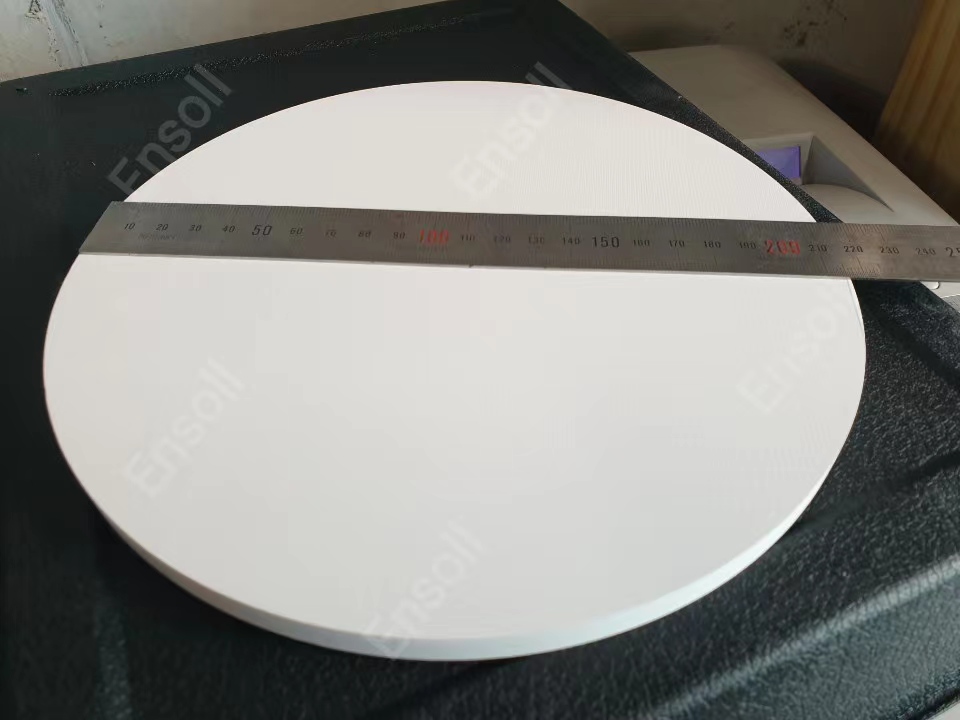

3.Alumina Ceramics Cutting Introduction

Viime vuosina, the cutting technology of ceramics in China has become increasingly sophisticated. In cutting industrial ceramics, diamond wire saws are newly used for cutting, with small slits and good cutting surfaces.

The important thing is that due to the increasing improvement and development of wire saws as far as possible next year, the price is more affordable than that of diamond band saws, and the cost of consumables is low, which has become more and more popular with ceramic manufacturers.

Alumina Ceramic